- Solutions

Vision & Awareness

Detection & Tracking

Weapon System Vision

Optical modules for semiconductor & industrial

- Technologies

Design

Fibre Imaging

Image Processing

Wavelengths

- Products

- About

SOLUTIONS

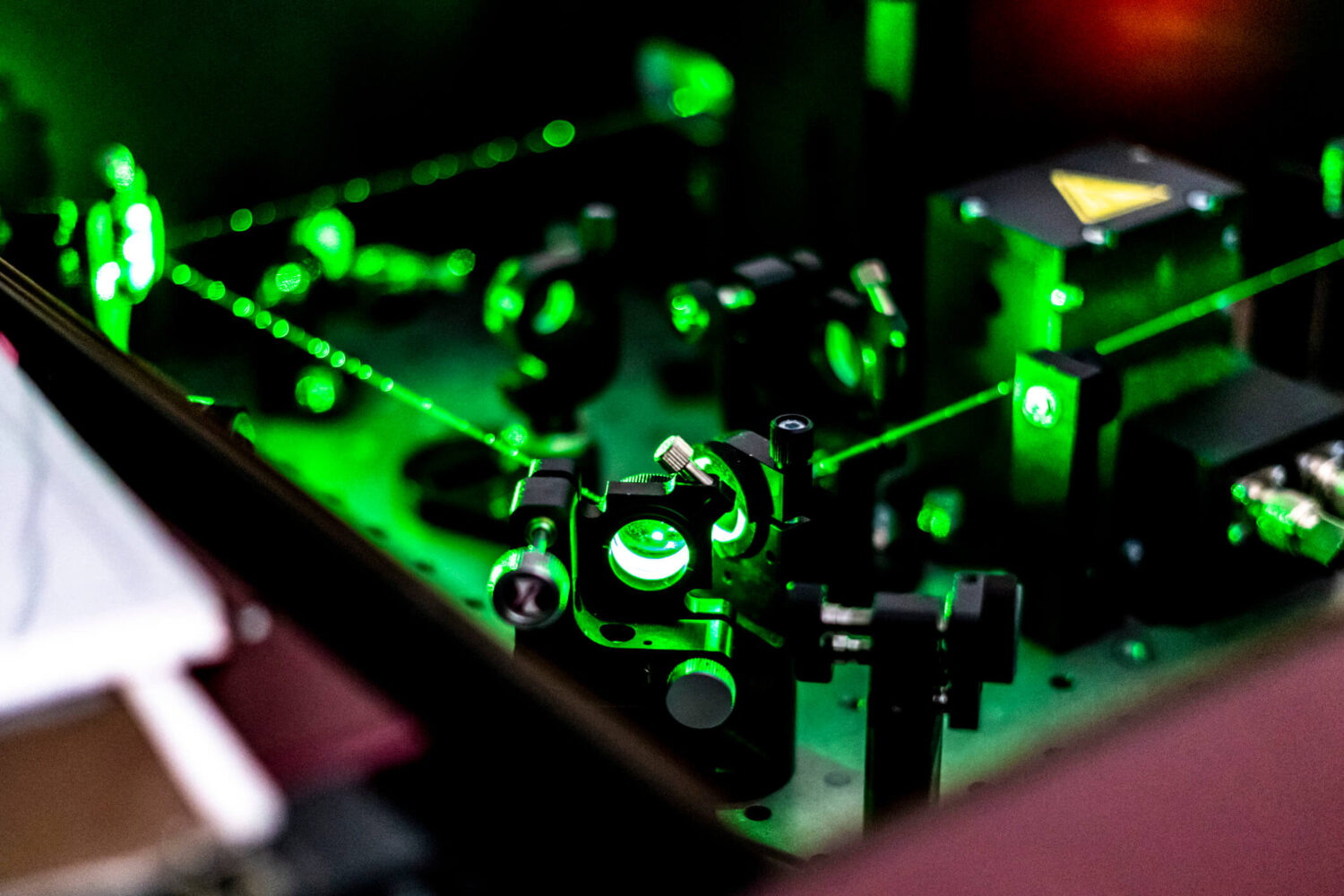

In semiconductor manufacturing, laser light needs to be very accurately delivered in applications like lithography and mask inspection. The laser beam(s) gets directed from one or multiple light sources to the application by smart use of optics and mechanics. Nedinsco develops and manufactures modules that measure and control the intensity, shape, focus and timing of the beam delivery to the exact right spot.

Consistent accuracy in laser-based systems, such as photolithography systems and wafer inspection systems, is critical to the success of semiconductor production. Even small deviations in laser beam intensity, focus or alignment can lead to yield problems or production stops. quality and performance output of the system.

Measuring and optimising the shape, intensity and focus of the laser beam ensures consistent performance throughout the production process. Advanced systems manipulate the beam with micrometre-level precision, enabling more efficient and reliable manufacturing of next-generation semiconductor devices with minimal defects.

Nedinsco manufactures a variety of modules for semiconductor chip production, from individual components to fully integrated assemblies. At Nedinsco, we provide a comprehensive range of services, carefully tailored to meet the specific needs of each client. With our advanced production capabilities, we ensure precision and maintain the highest standards of cleanliness. Additionally, we are fully equipped to perform all measurements and testing in-house.

At Nedinsco, we’re advancing semiconductor manufacturing with cutting-edge laser beam shaping delivery systems. Our systems carefully monitor, measure and control laser beams, ensuring the right intensity, focus and alignment for key applications like photolithography and mask inspection. With a focus on cleanliness and reliability, we provide high-performance solutions that keep production processes flawless. Based on our expertise we select the right optics and design the right mechanics around it to provide custom solutions to our customers. With a long history and experience in many applications we’re playing a key role in the development of next-generation semiconductor equipment with exceptional accuracy and consistency.

By combining technical expertise, innovation, and collaboration, we provide advanced solutions designed to address the unique challenges of various industries effectively.

At Nedinsco, our Semiconductor solutions are built on proven technologies and customized to meet your specific requirements, ensuring you achieve excellence. Curious about how we turn your challenges into optimal solutions? Explore our approach to find out more.